Pump Innovations in Liquid Handling Since 1911

About Us

Since 1911 Viking has been a pioneer in the positive displacement pump industry. High quality, fully tested pumps with strong foothold in respective applications has been a USP of Viking Pump over the years. Over 1400+ liquids can be pumped through Viking pumps. We have Over 245 authorized distributors in 68 countries to provide application support and service.

To know more give us a call on +918652603254

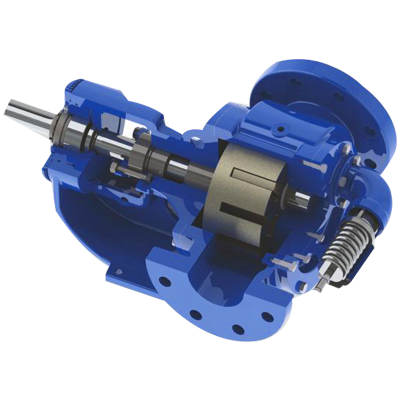

Universal Seal Series

The Universal Seal pumps are designed for a broad range of applications requiring continuous duty at pressures up to 200 psi. Even higher pressures are possible with high fluid viscosities at reduced operating speeds. They are applied to both thin and thick liquids, and operate equally well in either direction. They are also capable of operating under suction lift conditions.

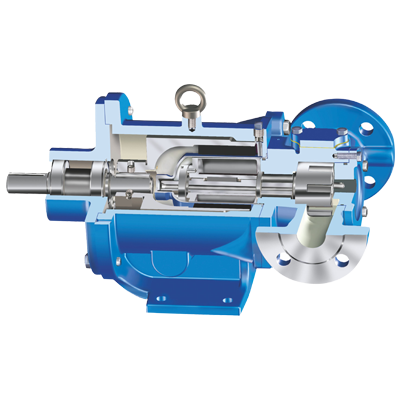

Universal Mag Drive Pumps

The Viking Universal Mag-Drive series is a leak-free magnet drive internal gear pump design which is ideal for pumping hazardous, hard-to-handle liquids and for applications where very low maintenance is important.

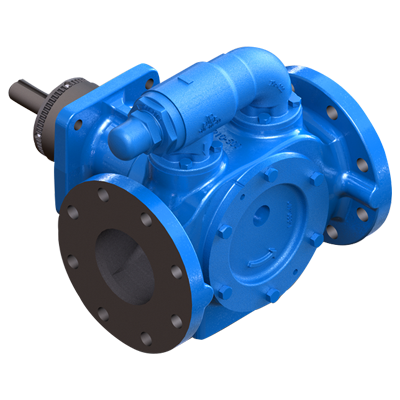

Motor Speed/ ViGEN

Technological advances in the science of flow, providing up to 460 gpm (104 m3/h) at motor speeds.

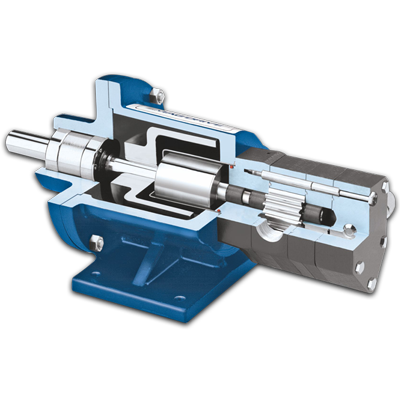

Spur Gear

The SG Series External Gear Pumps are designed for reliability in industrial applications through an extensive range of sizes and options with pressure capabilities upto 170Bar (2,500 PSI).

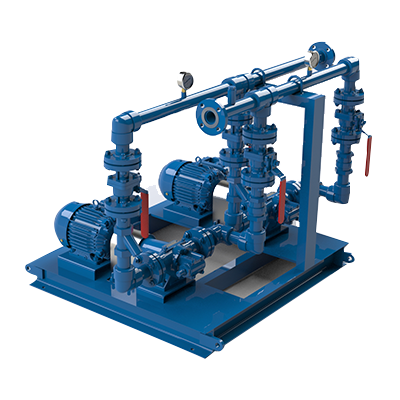

DFO Skid

Duplex Fuel Oil skid is used as an auxiliary supply support skid to the generators, boilers, etc for emergency fuel supply. Generators are used in housing societies, hotels, resorts, offices, companies, terminals, etc.

Capacity

1,600 GPM (365 M3/Hr)Viscosity

28 to 2,000,000 SSU (1 to 440,000 cst) with special construction

Pressure

2,500 PSI (170 BAR)Temperature

-120°F to +800°F (-85°C to +430°C) with special construction

Chemical

Petrochemicals

Oil & Gas