STERIDOSE

Magnetic Coupled Mixers for Pharmaceuticals & Biotech

Magnetic Mixers Trusted by Industries Across the Globe

Steridose comes with more than 40 years of manufacturing experience and expertise in the most advanced solutions in industrial mixers. With manufacturing units in North America and Center of Excellence in Sweden, we have a product range that grows via inventive additions. Our products have a presence in the manufacturing plants of leading biotech and pharmaceutical manufacturers around the globe. Steridose has a reputation for manufacturing state-of-the-art magnetic coupled mixers for pharmaceutical and biotech industries on a global scale In India, being part of IDEX India and under Material Processing Technologies group gives us an opportunity to serve customers in through our local IDEX India facility in Vadodara for sales & service support available locally.

Steridose Product Line

The Sterimixer can be configured to optimize flow or shear, depending on the application requirements. This results in a higher yield and a more efficient process.

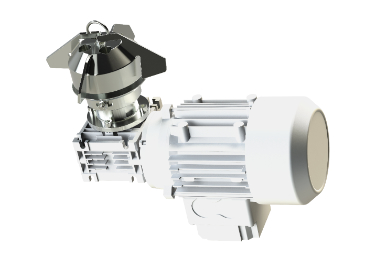

Sterimixer SMO (With Open Impeller)

STERIMIXER SMO

Open design impeller that is typically used for applications where high flow and low shear are required.

All surfaces are exposed to a cleaning solution when used with a properly drilled spray ball. It does not have to be submerged during cleaning.

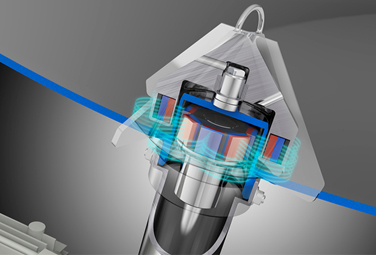

STERMIXER SMA

Closed design impeller used for high flow and low shear. Generates very low shear forces, making it ideal for applications involving shear-sensitive products, such as mammalian cell cultures. Patented flow channel where impeller rotates & centrifugal force draws fluid into area surrounding bearings & flushes it out through small holes on top of impeller, providing repeatable cleaning results. Open design impeller that is typically used for applications where high flow and low shear are required. All surfaces are exposed to a cleaning solution when used with a properly drilled spray ball. It does not have to be submerged during cleaning.

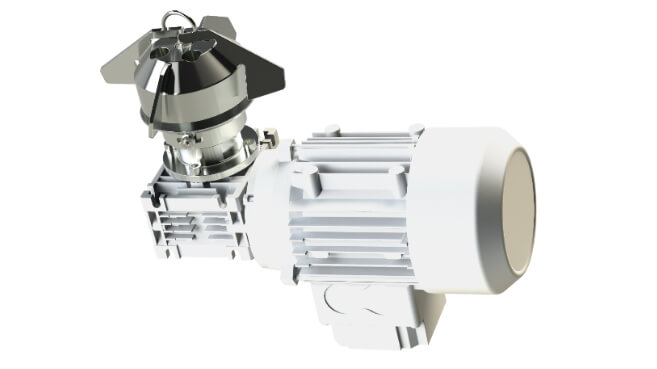

Sterimixer SMA (With Closed Impeller)

Sterimixer SMMS (With Medium Shear Impeller)

STERIMIXER SMMS

Open design impeller that provides higher shear forces, which are needed for applications where light or hydrophobic powders must be incorporated. All surfaces are exposed to a cleaning solution when used with drilled spray ball. Doesn’t have to be submerged during cleaning.STERIVALVE

Provides high-performance flow control for pharma & biopharma liquid process. Its hydrodynamically optimized geometry ensures that Sterivalve offers low flow resistances with a proven hygienic design. All moving parts in the actuator are completely isolated from the process fluids

Sterivalve

DOWNLOAD STERIDOSE BROCHURE

Steridose Features

Full Containment & Isolation

The proven magnetic coupling (no shaft or mechanical seal) means, improved containment.

Improved Clean ability

Easy and reliable cleaning using standard CIP and SIP procedures.

Low-Level Mixing due to bottom mount

Bottom mount mixer reduces the minimum mixing volume significantly to increase yields.

Ease of Maintenance from bottom mount and fewer parts

Safe and easy impeller & drive unit removal.

High Portability from Smaller Footprint

No overhead equipment needed; the mixer is installed safely on the bottom dish.

Biopharmaceuticals: Steridose Mag Mixers are used for below Steridose Application.

Upstream Processing Applications:

- Buffer Preparation tank and in holding tank

- Media (Micro-organism growth liquid) preparation tank and in holding tank

Bioreactor Applications:

- Liquid/liquid blending

- Maintaining particles in suspension

- Heat transfer

- Mass transfer (gas dispersion, aeration, oxygen transfer, CO2 ventilation, etc.)

Downstream Processing Applications:

- Tangential Flow Filtration (TFF)

- Chromatography

- Microfiltration (MF), Ultrafiltration (UF) & Infiltration (NF)

- Settling

Fill & Finish Stage Applications:

- Formulation Vessels

- Hold Tanks in Packaging Machines

Pharmaceuticals: Steridose Mag Mixers are used for below applications

Liquid Injectables

Parenteral

Mag mixers are commonly used at fill & finish steps are sterile stage requiring high level of containment & isolation.

Liquid Orals

Cough Syrups

Syrup is made out of up to 60-75% sugar solutions. Additives and active ingredient is added to the syrup and mag mixers are used for mixing.