Viking Pumps has been an industry leader and innovator since its foundation in 1911. Known as the pioneer of internal gear pump technology, the innovative designs of the pumps have been tested for various applications and delivered quality results.

Viking internal gear pumps are available in various metal of constructions i.e. Cast Iron, Ductile Iron, Carbon Steel, Stainless steel, Hast alloy etc.

Vikings advanced design Stainless Steel Gear Pump with cutting edge advanced engineering features is one of the most popular Internal Gear Pump in industry, used for highly corrosive, viscous & shearing liquids to handle low to high flow, temperature and pressure applications.

The success of this technology has given a new dimension to businesses to carry out their operations more efficiently and effectively. The Viking Internal Gear Pump is reliable, simple to operate and easy to maintain.

They are extraordinarily versatile and are extremely useful in handling thin liquids, fuel oil and solvents as well as thick liquids such as chocolate, asphalt and adhesives.

We are publishing herewith an insightful blog to have advantageous understanding of the applications of Internal gear pumps and right fit pump technologies.

Broadly pumps family is classified into Kinematic and Rotary PD (Positive Displacement) types. The internal gear pump is a sub-category of Rotary PD type pump.

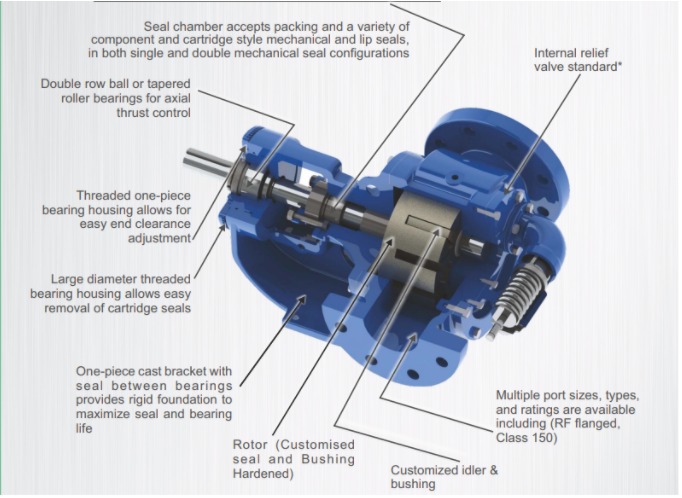

How does a Viking Internal Gear Pump work? Internal Gear Pump has one of the simplest & most efficient designs of pumps which consist of a casing that works as a pressure containing housing, a Rotor & Shaft which works as a driver and a small gear called idler. The idler gear fits within the rotor and rotates along with it over a pin called Idler pin mounted eccentrically on the head plate. The head plate also works as a cover for casing housing. The rotor is attached to the shaft which is coupled with a driver (generally an electric motor) that drives the pump. When the shaft rotates with the help of prime driver motor the gears un-mesh at the suction side of the pump and create a pressure drop (vacuum) pulling the liquid into the pump. This liquid is carried towards the discharge port. At the discharge port, the gears come into the mesh again, causing liquid to be pushed out. The crucial aspect here is that the pump does not develop any pressure in the entire process. It overcomes the back pressure acting on it and positively transfers the liquid from one end to another. The amount of back pressure that it can work against is directly proportional to the power it gets from the driver. Below are some of the main components of the SS Gear Pumps:- Casing: The pump casing is designed so it can be rotated on the bracket to any 45° or 90° angle for increased versatility of installation and complete selection of ports. Pump casing can be rotated in various angles permitting eight different port positions. It holds the head plate assembly and internal PSV.

- Rotor & Shaft: There are two interlocking gears of different sizes with one rotating inside the other. The larger gear (the rotor) is an internal gear i.e. it has the teeth projecting on the inside. Within this is a smaller external gear (the idler – only the rotor is driven) mounted off-centre designed to interlock with the rotor.

- Bracket: Bracket is a key component in the internal gear pump which holds the casing , bearing housing , rotor & shaft assembly and cast-in stuffing box. Vikings universal seal bracket design can accommodate all kinds of standard seals and gland packing without any change in the stuffing box. Single Piece brackets also ensure accurate alignment of the rotor & shaft assembly and reduce the leakage issues.

- Idler and Bushings: Idler as the name sounds is a driven gear run on an idler pin which is fitted in the head plate also known as the Cover plate. Idler helps in creating the required pressure gradient while mashing in and out with the rotor.

- Internal RV: As internal gear pumps are positive displacement pumps , any choking or blocking in the discharge line will result as excess pressure rise which can damage the pump internal or piping etc. Internal RV or pressure safety relief valve is provided to protect the pump from excess pressure . Viking Pumps are equipped with a unique feature of Internal PSV which is designed for 100% bypass if subjected to high pressure.

- Bearing Housing: Bearing housing contains the ball / roller bearing to provide axial and radial thrust control to rotor shaft assembly. Viking unique DOUBLE THREADED design allows accurate fitment of the bearing and end clearance setting of the rotor.

-

- All varieties of refined fuels & lubricants

- Resins & polymers

- Alcohols & solvents

- Polyurethane foam (isocyanates, polyols & additives)

- Food products such as corn syrup, chocolate & peanut butter

- Paint, inks & pigments

- Soaps & surfactants

- Heat transfer fluids

- Adhesives

- Various catalyst and Adhesives

- Polymers,

- Coagulants, Corrosion Inhibitors

- All varieties of refined fuels & lubricants

- Asphalt / Bitumen

- Coal Tar and Graphite Pitch

- Solvents and Resins

- Various Hydrocarbons, Crude or Residue Oils

- Thermic Fluids