Industrial mixers are used in a wide range of industries to mix, blend, dissolve, or disperse two or more substances into a homogeneous mixture. These mixers come in various types, including bottom-mounted mixers, magnetic mixers, and in-tank mixers.

Types of Industrial Mixers

Primarily, there are three types of industrial mixers:- Bottom-mounted

- Magnetic

- In-tank

Bottom-mounted mixers are used for applications with high flow and low shear requirements. Magnetic mixers use a magnetic coupling to drive the impeller, providing improved containment and easy cleaning using standard CIP and SIP procedures. In-tank mixers are designed to be used inside a tank or vessel to provide mixing or agitation of the contents.

Bottom-mounted Mixers

Bottom-mounted mixers are a popular choice in situations where there are limitations on headroom that prevent a top-mounted installation. They are also preferred when the mix head needs to be positioned close to the bottom of the vessel for tasks like pre-mixing or small batch processing. The use of bottom-mounted mixers is gaining traction due to their advantages, which include a reduced risk of contamination, user-friendly operation, and the ability to handle low minimum mixing volumes.

Magnetic Mixers

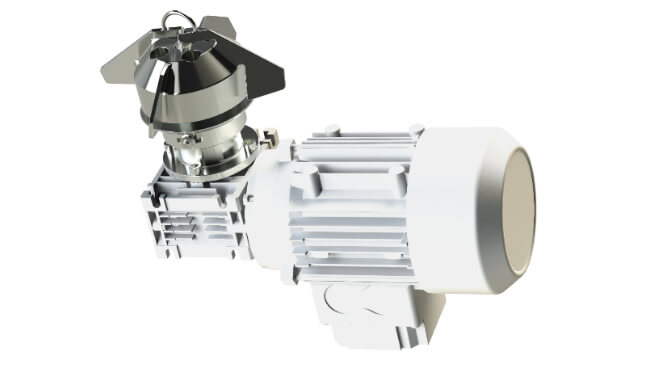

Magnetic mixers employ unique magnetic driving and non-sealing technology, setting them apart from conventional gear-drive agitators. A magnetic mixer transmits torque from the drive to the impeller through magnetic couplings and the magnetic field. Unlike traditional methods, magnetic mixers do not require penetrating the vessel shell or using mechanical seals. This design eliminates the risk of toxic or valuable media leaking out of the vessel.

In-tank Mixers

In-tank industrial mixers are employed to transform a non-uniform physical system into a more uniform mixture. Horizontal industrial mixers consist of a stationary tank housing an agitating mechanism. This stirrer facilitates the movement of particles within the mixing tank, transferring them in groups from one location to another. Stirring mediums such as ribbons or blades can be used for this purpose.

Common Applications for Industrial Mixers

Industrial mixers are used in a wide range of industries for various applications. Some common applications for industrial mixers include chemical make-up, solids suspension, pH control, additive blending, wastewater treatment, temperature control, emulsification, gas dispersion, and dynamic inline blending in the chemical manufacturing industries.

Industrial mixers are also used in the mining industry for applications such as gold leaching, CIL and CIP, cyanide destruction, pipeline slurry storage, attrition scrubbing, solvent extraction, conditioning tank mixing, storage, and mining wastewater.

Industrial mixers are also commonly used in the food, pharmaceutical, everyday chemical, and cosmetic industries for mixing, blending, and combining a variety of substances.

Advantages of Using Industrial Mixers

There are several advantages to using industrial mixers. These include improved mixing efficiency, reduced processing time, increased product consistency, and reduced waste. Industrial mixers can also help improve product quality by ensuring that all ingredients are thoroughly mixed and evenly distributed.

Steridose by IDEX

Steridose, a division of IDEX, specialises in providing magnetic-coupled mixers and radial diaphragm valves designed specifically for biopharmaceutical plants. Their Sterimixer product line offers configurable options to optimise flow or shear, tailored to meet the specific needs of each application. This customisation leads to increased yield and improved process efficiency, enhancing overall productivity.

Conclusion

Industrial mixers play an important role in many industries by improving mixing efficiency, reducing processing time, increasing product consistency, and reducing waste. Steridose by IDEX offers a complete range of industrial mixers that are technologically advanced and optimised to meet customer needs.