FlexSift S20 Flair

Rotary Sifter

De-agglomeration & Security Screening

Introducing Quadro FlexSift S20 Flair

Quadro security® FlexSift is the cutting-edge technology used for high-capacity screening and de-agglomeration application

FlexSift S20 Flair from Quadro is designed on the rotary sifting technology. Its design has been developed after collaboration and listening to the customer needs in pharmaceutical industry to improve sifting efficiency of difficult powders and to enhance overall productivity as compared to the vibratory sifter.

Benefits of Rotary Sifter

compared to Vibratory Sifters

Reduced sifting time

to ensure higher capacity throughput

Nearly 100% product

recovery

Reduced cleaning time

Eliminate manual intervention

Reduced no. of sifters. Minimal footprint for maximum space efficiency

Reducing air-borne fine particles, minimizing product waste & limiting operator exposure

Easy to integrate with gravity feeding and vacuum transfer lines

Features

Unique Features

Seamless Sifting

In-process cleaning of perforations through purging for uninterrupted processing

Unique Design

Minimizes product retention at end of process

Unmatched Flexibility

Flexibility to use as Conical Mill

Standard Features

Compact, in-line design

Low profile design fits below most bulk bag unloader and mixer discharges

Positive, 360º discharge

Effectively segregates and retains impurities & other foreign materials cutting sifting times up to 80%

Easy-to-clean/maintain

Minimal no. of parts – single bolt locking mechanism secures screen assembly onto gearbox for fast changeover & maintenance Quick screen changes with no special tools required

User Friendly Design

- Motorized height adjustable stand

- Easy to use HMI based controls as standard

- Suitable for vacuum feed or gravity feed

- Range of spindle lengths available

Technical Specifications

S20 Flair Typical Capacities

Application

S20 Flair series is the ideal solution for pharma formulation & API, Food ingredients, cosmetics and chemicals for screening & deagglomeration of the most difficult to handle powders.

Meets FDA and cGMP standards for safe processing of pharmaceutical powders, food ingredients, cosmetics etc.

Rotary Sifting Technology

Quadro security® FlexSift rotary sifting is the cutting-edge technology used for high-

capacity screening and de-agglomeration application

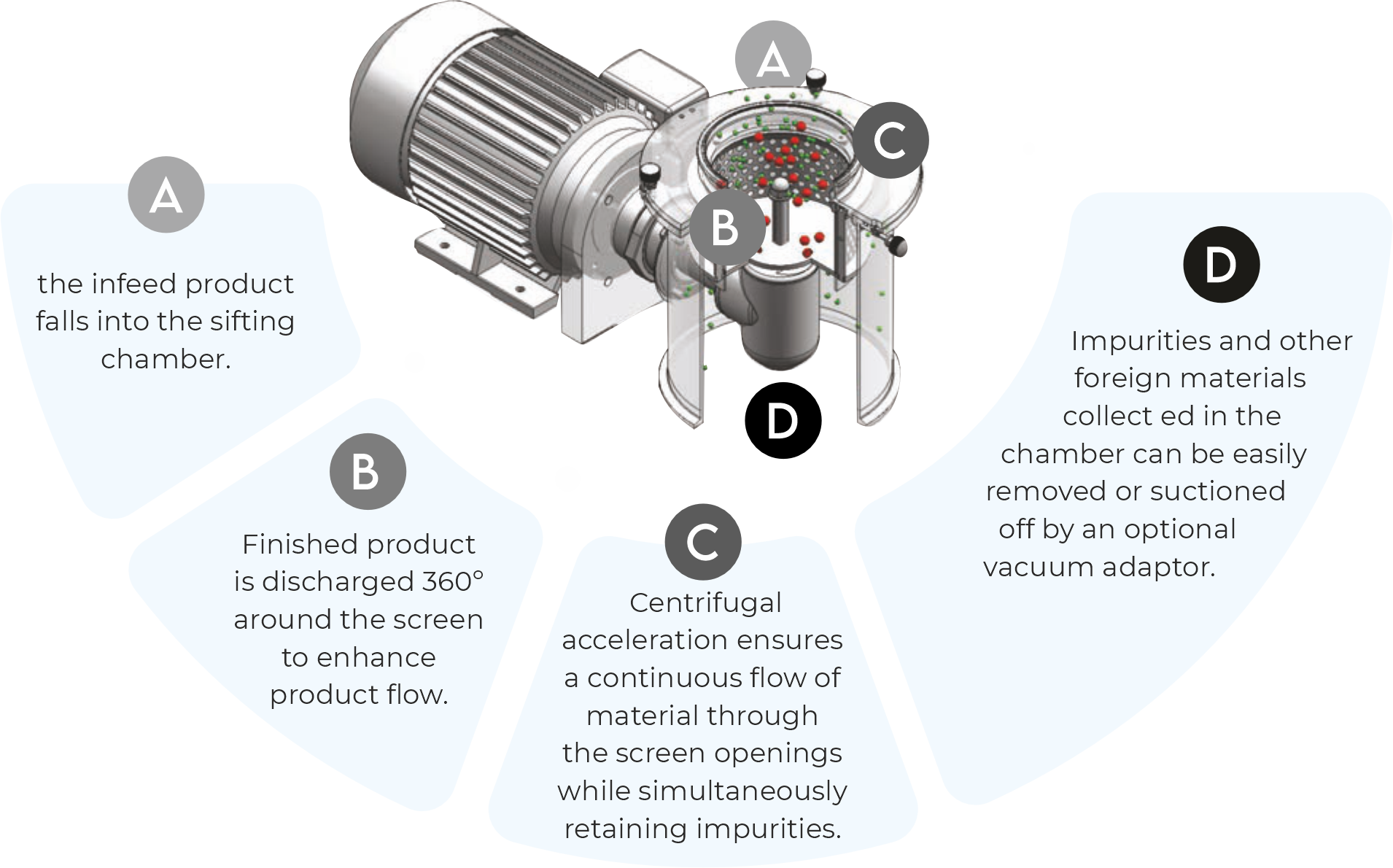

FlexSift S20 Flair rotary sifter works on Principal of Centrifugal force which enables screening by pushing the product particles through a mesh. Impurities and other foreign materials collected in the chamber can be easily removed or suctioned off. Finished product is discharged 360º around the screen to enhance product flow. The rotating action of the FlexSift combined with the custom designed spoiler arm gently deagglomerates the powder without reducing the size of the particles. Delivers fast, efficient powder-sifting capabilities with nearly 100% product recovery.

Different size screens are available ranging from 6.0 mm to 0.225 mm corresponding to various mesh sizes to suit your application. A simple bolt-locking mechanism secures the screen assembly to the gearbox facilitating rapid changeover and maintenance.

Let’s Get Started

Contact our expert to assist in your powder screening process to ensure that your

powders are free of foreign particles with uniform particle size.