In the world of manufacturing, precision is of utmost importance, and a vital instrument in achieving this precision is the positive displacement meter. But what is a positive displacement meter used for? Join us as we dive into the domain of Positive Displacement Flow Meter manufacturers and explore the indispensable role played by the products in achieving manufacturing finesse.

Understanding Positive Displacement Meters

Positive displacement meters are devices that measure the flow rate of fluid by dividing it into small, quantifiable increments. These meters are essential for accurately measuring and controlling fluid flow in manufacturing, ensuring efficiency and accuracy in various processes.

Positive displacement meters are a type of flow meter that measures the volume of fluid that passes through a pipe by trapping a fixed amount of fluid and then counting the number of times the fluid is displaced. They are a versatile and accurate way to measure fluid flow and are used in a wide variety of manufacturing industries.

A positive displacement meter works by trapping a fixed volume of fluid in a chamber. As the fluid flows through the meter, the chamber is filled and then emptied, and the number of times this happens is counted. The flow rate is then calculated by dividing the total volume of fluid by the number of times the chamber has been filled.

Positive displacement meters are available in a variety of designs, including rotary vane, oval gear, and piston meters. Each type of meter has its own advantages and disadvantages, and the best type for a particular application will depend on the fluid being measured, the flow rate, and the pressure requirements.

Applications in the Manufacturing Industry

So, what is a positive displacement meter used for? These meters find extensive use in various manufacturing applications, such as Positive displacement meters are used in a wide variety of manufacturing industries, including:

- Chemical processing: Positive displacement meters are used to measure the flow of fluids in chemical processes such as the production of plastics, pharmaceuticals, and fertilisers.

- Food production: Positive displacement meters are used to measure the flow of fluids in food production processes, such as the production of beverages, dairy products, and baked goods.

- Pharmaceutical manufacturing: Positive displacement meters are used to measure the flow of fluids in pharmaceutical manufacturing processes, such as the production of vaccines, drugs, and medical devices.

- Oil and gas: Positive displacement meters are used to measure the flow of oil and gas in pipelines.

- Water and wastewater treatment: Positive displacement meters are used to measure the flow of water and wastewater in treatment plants.

Advantages of Positive Displacement Meters

The benefits of utilising positive displacement meters in manufacturing processes are plentiful. They excel at precision, ensuring highly accurate measurements of flow rates. These meters are known for their reliability and are capable of enduring even the most challenging operational environments. They exhibit versatility by effectively measuring a wide array of fluids, including liquids, gases, and slurries. Moreover, their adaptability extends to various applications, rendering them a valuable and versatile tool for manufacturers across different industries.

Types of Positive Displacement Meters

There are several types of positive displacement meters available from various Positive Displacement Flow Meter manufacturers, including rotary vane, oval gear, and piston meters. Each type has its own unique advantages and is suited to specific manufacturing applications.

Rotary vane meters: Rotary vane meters use a rotating vane to trap a fixed volume of fluid. As the vane rotates, the fluid is displaced, and the flow rate is measured. Oval gear meters: Oval gear meters use two gears that mesh together to trap a fixed volume of fluid. As the gears rotate, the fluid is displaced, and the flow rate is measured. Piston meters: Piston meters use a piston to trap a fixed volume of fluid. As the piston moves, the fluid is displaced, and the flow rate is measured.IDEX – The Leading Positive Displacement Flow Meter Manufacturers

IDEX’s Positive Displacement Flow Meters are precision-made liquid-measuring flow meters. They are designed to provide high-accuracy positive displacement (PD) meters. These metres are part of IDEX’s Fluid & Metering Technologies, which also include pumps and systems that move, measure, and manage high-value liquids, gases, and solids.

One of the products in their range is the Liquid Controls Positive Displacement Flow Meters. They are exclusively engineered with a TRI rotor design that has no metal-to-metal contact within the measuring chamber. This unique design results in minimal wear and tear, sustains accuracy for a longer time, and results in low operating costs.

The M and MA Series Mechanical Diaphragm Pumps are robust and reliable spring-return mechanical diaphragm pumps. The double-layer PTFE membrane grants high chemical compatibility, and the pump body is made of aluminium and coated through a cataphoresis process to increase resistance to chemical and atmospheric agents.

The M and MA Series rotary motion positive displacement metres offer the ultimate in measurement accuracy for custody transfer of petroleum products, aviation fuels, LPG, and a broad range of industrial liquids. The unique cast-case construction of the M and MA Series metres results in low pressure drops for most liquids, delivering superior performance with minimal demand on system pumps.

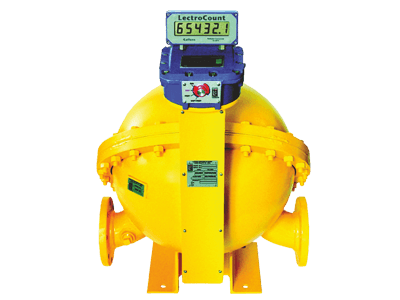

The MS Series metres are ideal for bulk measurement of product during loading and unloading of tanks, transports, railcars, ships, barges, and more. The MS Series metres are housed in a spherical steel case for higher system pressure applications up to 1,440 PSI.

Conclusion