Powder Handling Technology

With more than 40 years of powder handling experience behind us we’ve seen and solved the challenges you face every day. Matcon designs and manufactures powder handling equipment that can be used to improve manufacturing processes across a range of applications. At the heart of our Powder Handling System is an IBC fitted with our patented Cone Valve Technology, a unique discharge valve that eliminates typical powder flow problems.

Cone Valve Systems for Solving

Powder Handling Challenges

Matcon’s powder handling equipment includes our patented Cone Valve Technology, which ensures that we can overcome all manner of powder flow and containment problems. The Cone Valve is used to control a wide range of bulk materials in powder and tablet form, either as a raw material or blended finished product.

Profitable and Successful powder

handling solutions

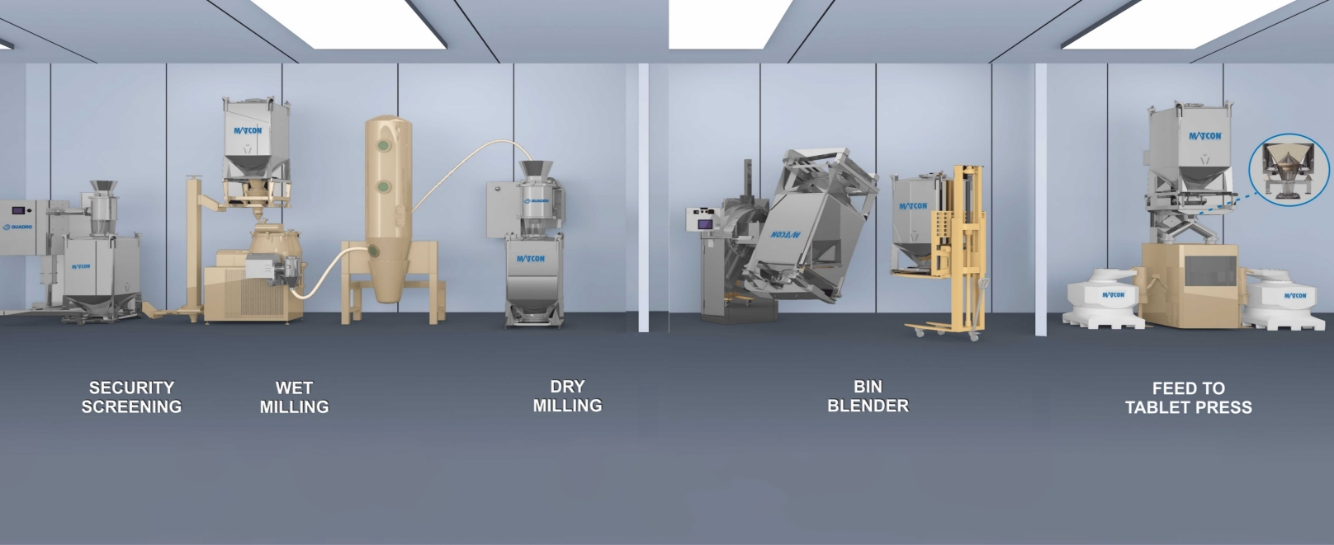

Matcon creates flexible, safe and agile production facilities that enable manufacturers to produce better products with a wider variety and batch sizes. Our processing equipment helps you at every stage of your powder handling process, streamlining your operations, improving product quality and helping increase your margins.

Benefits of Using Matcon IBC

Cone Valve Systems

The Matcon system is based on using IBCs (Intermediate Bulk Containers) to transport powders between the manufacturing steps and to blend powders in.Matcon has a range of IBC solutions for effective powder containment, transfer and processing, all designed to meet the demands of your industry.

Key Benefits:

Highest hygiene & safety

requirement

No product trapping

or contamination

Available for small, regular and large batches

No need of ancilliary

feeders

Prevents traditional powder

handling issues

Easy to clean