Pumps are the unsung heroes of many industries, playing a crucial role in various processes. But why are pumps important in the industry? The next most-obvious question appears – where are pumps used in industry? They are used to move fluids, a fundamental requirement in many industrial applications. From the butterfly valve used in controlling flow to the different types of pumps like internal gear pumps, stainless steel gear pumps, and cast iron gear pumps, each has its own unique role. Let’s delve deeper into this topic and also look at some leading pump manufacturers.

Understanding the Role of Pumps

Pumps are mechanical devices that move fluids through mechanical action. They are essential components in industrial processes as they enable the movement of fluids, slurry, solids, semi-solids, and powders, which are crucial for various applications. Whether it’s transferring water from a reservoir to your tap or circulating coolant in an engine, enabling the production of life-saving medicines or out-of-this-world chocolates, pumps make it all possible. Pumps help execute a number of crucial tasks, like:

- Transport fluids from one place to another.

- Provide the necessary pressure for industrial processes.

- Mix and blend fluids.

- Control the flow of fluids.

- Remove contaminants from fluids.

Types of Pumps

There are several types of pumps used in industries, each designed for specific applications. Some common types include centrifugal pumps, positive displacement pumps, and specialty pumps like the gear pump. Each type has its own unique characteristics and uses. Each of these pumps has specific usage and functions across industries. Let’s take a look at those:

Centrifugal Pumps

Centrifugal pumps are the most common type of pump used throughout the industry. They are used to move a variety of fluids, including water, oil, and chemicals. Centrifugal pumps work by rotating an impeller, which creates a centrifugal force that forces the fluid to move through the pump. Centrifugal pumps use a rotating impeller to move fluids. They’re commonly used in various industrial processes due to their ability to handle large volumes of fluids and provide smooth flow rates. A cast-iron gear pump is one such type of centrifugal pump known for its durability and efficiency.

Positive Displacement Pumps

Positive displacement pumps move fluids by trapping a fixed volume of fluid and then displacing it. This type of pump is often used for applications where precise flow rates are required. Positive displacement pumps include gear pumps, lobe pumps, and vane pumps. Positive displacement pumps include internal gear pumps and stainless steel gear pumps. These pumps work by trapping a fixed amount of fluid and then forcing (displacing) that trapped volume into the discharge pipe. They are suitable for certain industries due to their ability to handle varying viscosities and pressures.

Reciprocating Pumps

Reciprocating pumps move fluids with a piston or plunger that moves back and forth. They are a type of positive displacement pump often used for applications where high pressures are required, like the cleaning of sewer lines, the oil industry, and pneumatic pressure systems. Piston pumps, plunger pumps, and diaphragm pumps all make up the spectrum of reciprocating pumps.

Diaphragm Pumps

Diaphragm pumps, also known as membrane pumps, are a type of positive displacement pump that uses a combination of the reciprocating action of a rubber, thermoplastic, or teflon diaphragm and suitable valves on either side of the diaphragm to pump a fluid. These valves can be anything ranging all the way from check valves, butterfly valves, flap valves, or any other form of shut-off valve. They are highly reliable because they do not include internal parts that rub against each other. This type of pump is often used for applications where there is a risk of contamination, like chemical processing, the handling of abrasive sludge and slurries, and production lines with corrosive solutions and highly viscous liquids.

Screw Pumps

Screw pumps are a type of positive displacement pump that uses one or more screws to move fluids or water along the axis of the screw. Screws within the pump work together in a synchronised manner to pressurise and propel fluids through the system. This mechanism finds widespread use across multiple industries, including power generation, shipping, chemical processing, terminals, refineries, pipelines, and oil and gas production. It’s a fundamental component in these sectors, enabling the efficient movement of fluids for various applications.

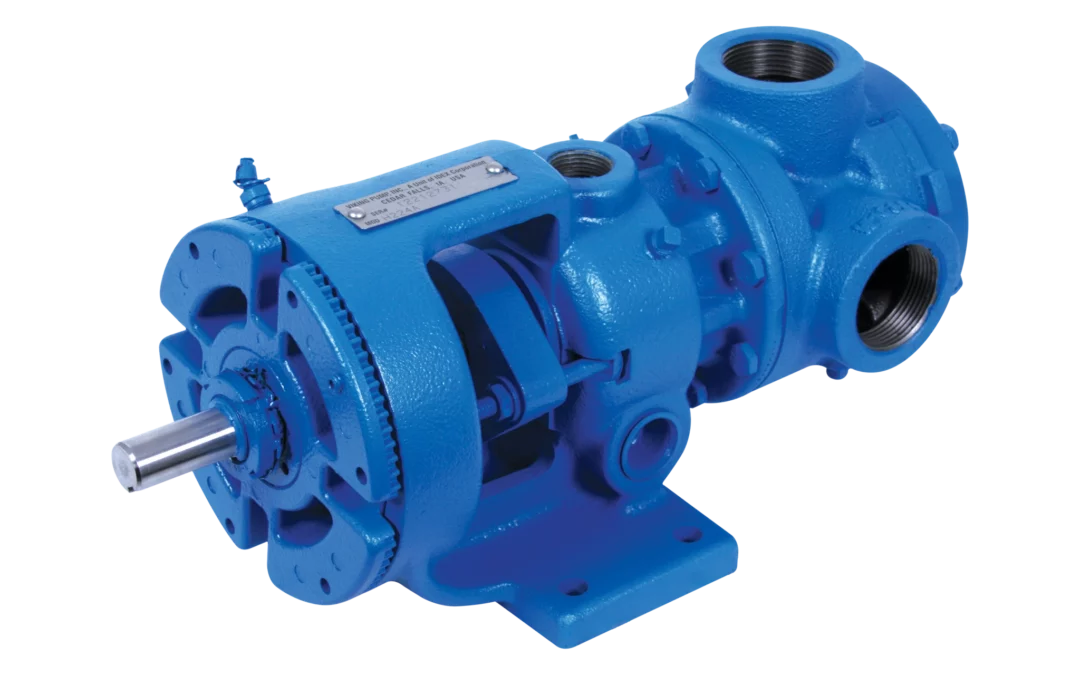

Gear Pumps

Gear pumps are a type of positive displacement pump that uses one or more gears to move fluids or solids along the axis of the screw. They are often used for applications where high pressures or low flow rates are required, such as hydraulic fluid power applications and chemical installations with the need for high viscosity pumping, such as oils, paints, plastics, soaps, and adhesives.

Applications in Various Industries

Pumps play a vital role in a wide range of industries, such as oil and gas, chemical, pharmaceutical, and manufacturing. For instance, butterfly valves are used in industries to regulate fluid flow through a section of pipe. The versatility and adaptability of pumps make them indispensable in these sectors.

Importance of Pump Quality

The quality of pumps used in industrial operations is paramount. High-quality pumps ensure efficient operation and longevity. Therefore, choosing reputable manufacturers becomes crucial. Leading pump manufacturers prioritise quality, ensuring their products meet the highest standards.

IDEX Pumps – The Trusted Name for Decades

IDEX is a trusted name when it comes to high-quality pumps. With a legacy built on reliability and innovation, IDEX pumps are used across industries for varied purposes. IDEX’s application-specific products provide solutions to most fluid handling needs. They are precision-engineered pumps, metres, and systems that move, measure, and manage high-value liquids, gases, and solids. Within the pump and flow metering world, IDEX businesses are recognised for their expertise in the precise handling of corrosive, abrasive, viscous, extreme temperature, fine particle, and many other challenging applications.

ConclusionPumps play a critical role in various industries. Their ability to move fluids makes them an integral part of many industrial processes. Whether it’s an internal gear pump or a stainless steel gear pump, each type has its own unique role and importance. So next time you come across a pump, remember the crucial role it plays! For your pump needs, don’t hesitate to reach out to leading pump manufacturers like IDEX.