The chocolate industry in India is on the rise, with an estimated production of 400,000 metric tonnes by 2025. To cater to this increasing demand, manufacturers need efficient pumps for chocolate industry. Among the pump options,

Viking pumps emerge as the pick for chocolate producers in India.

Challenges in Pumping Chocolate

Chocolate, known for its flavour and texture, poses challenges for pumps due to its distinct characteristics. Firstly, its viscosity varies based on factors like type and cocoa content, necessitating pumps that can handle the consistency commonly found in chocolate pastes and fillings. Secondly, the fragile nature of cocoa particles makes chocolate susceptible to forces during pumping, which could affect its quality and taste. Abrasive components like cocoa solids in chocolate can cause wear and tear on pump parts. Lastly, given chocolates sensitivity to temperature fluctuations, precise temperature control is crucial to avoid issues like seizing or burning during pumping operations.

How Viking Pumps Address These Challenges

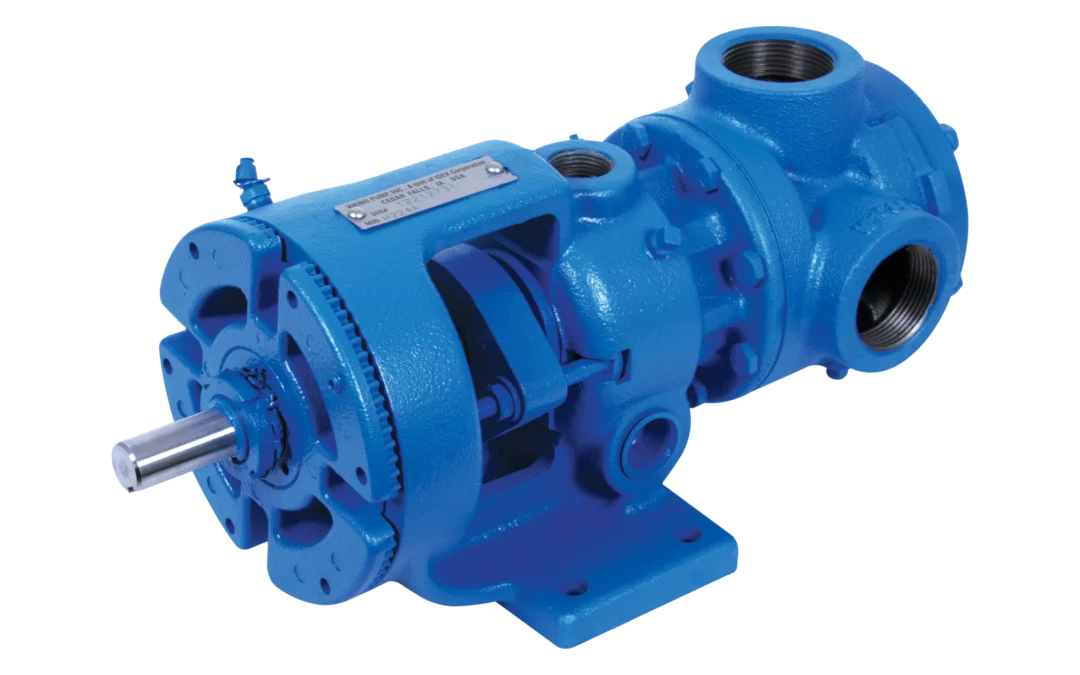

Viking Pumps are well known for their internal gear design, which provides tailored benefits perfectly suited to the needs of the chocolate industry. Viking pumps guarantee a flow regardless of changes in pipeline pressure. This is crucial for maintaining product quality and preventing any fluctuations. Their design, which minimises shearing forces, helps protect cocoa particles, preserving the texture and flavour of chocolate. Made from materials such as steel and tough cast iron,

Viking pumps can withstand the harsh nature of chocolate ingredients, ensuring long-lasting performance. Their gentle handling process reduces product deterioration, ensuring quality throughout production. Viking pumps offer features like jacketed casings and external circulation systems for temperature control during chocolate pumping tasks. It is these features and benefits that make Viking one of the ideal

pumps for chocolate industry.

IDEX Viking, One of the Ideal Pumps for Chocolate Manufacturers in India

IDEX, the company behind Viking Pumps, provides a range of pump solutions tailored specifically to meet the needs of the chocolate industry. These pumps are designed to handle the viscosities encountered in chocolate production, from cocoa butter to thick pastes. They prioritise simplicity in design for cleaning and maintenance, essential for maintaining hygiene standards in food processing settings. IDEX offers support to Indian chocolate manufacturers through accessible sales channels and dedicated service options established within India.

Additional Advantages for Indian Chocolate Manufacturers

Apart from their expertise, Viking Pumps offers a range of benefits to chocolate manufacturers. Known for their reliability and lasting performance, Viking pumps help cut down on maintenance costs and last a longer time, resulting in a higher return on investment. Designed to be energy efficient, these pumps consume energy, supporting manufacturing practices and reducing overall operational expenses. IDEX ensures that Viking pumps meet food safety standards, ensuring product safety and hygiene in the food processing sector, thus making it one of the most preferred

pumps for chocolate manufacturers in India.

Exploring Advanced Uses of Viking Pumps in Chocolate Production

While Viking Pumps are highly skilled at chocolate transfer tasks, they go beyond pumping functions. These pumps excel at metering and dosing applications to ensure the dispensing of ingredients like cocoa butter, lecithin, or sugar for consistent recipes. They seamlessly integrate into filling and depositing processes to enable the transfer of chocolate into moulds or packaging with controlled precision. They cater to the viscosity requirements needed for filling types of chocolates ranging from pralines to truffles.

Viking pumps play a role in the process of gently applying chocolate to confectionery items without disrupting their structure, thus preventing cracking or inconsistencies in the final product. In the realm of bean-to-bar chocolate production,

Viking pumps showcase their versatility by assisting in the transfer of materials like cocoa liquor and cocoa mass throughout the process, ensuring operations and high-quality end results.

Selecting the Appropriate Viking Pump for Your Requirements

When deciding on the Viking pump model for your chocolate processing needs, there are key factors to consider. Firstly, it is essential to evaluate the flow rate and pressure to ensure that the chosen pump has the capacity to meet operational requirements effectively. Taking into account the viscosity of the chocolate being processed is crucial when choosing a pump size and model that can handle its consistency. Material compatibility is another consideration; selecting pump materials, such as steel, that comply with food safety regulations and are suitable for use with chocolate products is vital. Furthermore, giving priority to pumps with designs that facilitate cleaning and maintenance can facilitate operations while consistently meeting hygiene standards.

By collaborating with an expert from

Viking Pumps and taking these aspects into consideration, chocolate makers in India can make informed choices. Select the perfect Viking pump to enhance their production processes and ensure the consistent excellence of their delightful creations.

Conclusion

Viking Pumps, known for their design, sturdy build, and focus on product handling, stand out as the top choice for chocolate manufacturers in India. Their capability to manage viscosities, reduce effects, and uphold steady chocolate quality, along with their durability, ease of upkeep, and global support network, positions them as a valuable resource for any chocolate production venture. As the Indian chocolate sector continues to thrive,

Viking Pumps will undoubtedly play a role in its success story.