A dosing pump is a positive displacement pump that is designed to inject a chemical or

any other substance into the flow of water, gas or steam. Dosing pumps are typically

small and provide an extremely precise flow rate for maximum control. They are applied

to a wide range of industrial applications, from wastewater treatment to food processing.

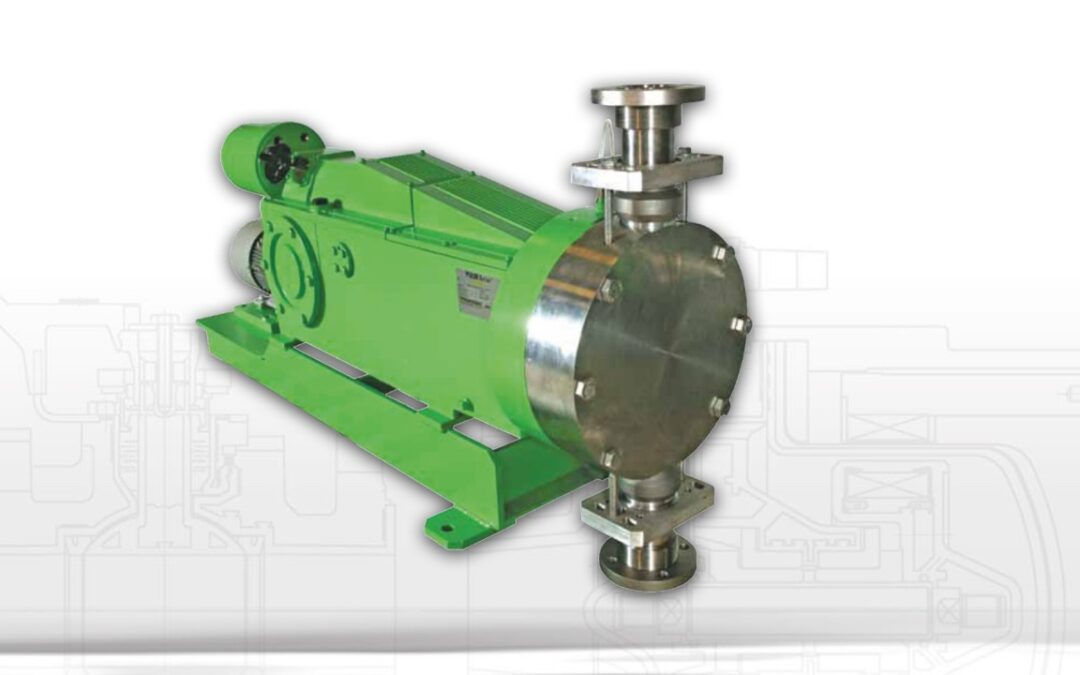

Pulsafeeder, as a part of IDEX India, is the leader in dosing pump manufacturer in India is known and trusted in the market for its rugged construction, dependable

performance and API 675 compliance. The dosing pump from Pulsafeeder offers the

highest level of manufacturing excellence and quality control.

IDEX is a global fluidics leader serving high growth specialized markets and known for

our highly engineered fluid handling pumps and systems to provide the best to our

customers.

How does a Dosing Pump work?

Dosing pumps also known as metering pumps are available in a variety of types and

provide many years of reliable and efficient operations. In most dosing

applications, the accuracy of dosing is very important. The operation of a dosing pump

is based on the principle of a positive displacement pump.

The major part of these pumps is a valve that will suck the chemical liquid from the

chemical tank to the pump. The pumps are built with a switch that gives an alarm when

the chemical liquid has decreased. With the use of a piston or plunger, the dosing pump

forces the fluid from the inlet to the outlet of the pump.

What is the function of a Dosing Pump & where it is used?

As mentioned above the chemical injection package serves the purpose of injecting a

precise dose of chemicals accurately into a system with the required back pressure,

either continuously or intermittently. Pulsafeeder has the Pulsa and PulsaPro Series

hydraulic diaphragm pumps that are a benchmark of safety, reliability, accuracy and

efficiency. It is primarily used in the Oil & gas, Base Chemicals, Speciality Chemicals,

Agro Chemicals, Water & Wastewater, Refinery, Petrochemicals, Power and Chemicals

industry.

PulsaPro- TECHNICAL SPECIFICATIONS

● Pump Design: Fully compliant API standard 675, 3 rd edition

● Flows and Pressures – 0.4 to 768 LPH

● Accuracy – +/- 0.5%

Pulsa Series – TECHNICAL SPECIFICATION

● Pump Design -Complying to API-675 3rd edition

● Flow & Pressures – 9.5 to 9100 LPH

● Accuracy – +/- 1.0%

What makes Pulsafeeder metering pumps different from our competitors?

– Pioneers of hydraulically actuated diaphragm metering pumps

– Fully compliant API standard 675, 3rd edition

– Modular Design

– Internally designed Auto stroke controller

– Power Dense

– Better flow accuracy

– Hydraulic Diagnostic Package

Pulsafeeder dosing pumps move precise volumes of liquid in a specified time period to

provide accurate flow rates. The Pulsa and PulsaPro Series hydraulic diaphragm pumps

are a benchmark of safety, reliability, accuracy and efficiency. They have a variety of

diaphragm styles manufactured with high levels of precision for the most demanding

applications to deliver safe, remote and accurate dosing.