The air-operated double diaphragm pump, commonly known as the AODD pump or diaphragm pump, is a type of positive displacement pump that uses compressed air as a power source to move fluids. A pneumatic air pump is a suitable alternative for applications where electrical power is not available or where the risk of electric shock or explosion is high.

One of the most significant advantages of the air-operated double diaphragm pump is its portability. These pumps are designed to be lightweight and compact, making them easy to transport and install. Portable pumps are commonly used in various industries, such as oil and gas, chemical, food and beverage, pharmaceutical, and mining.

When it comes to efficiency, the air-operated double diaphragm pump is a preferred choice. This pump is designed to handle a wide range of fluids, including corrosive and abrasive fluids. Unlike other pumps, the diaphragm pump can operate dry without causing damage to the pump. The design of the pump allows for self-priming, meaning that the pump can automatically remove any air in the suction line.

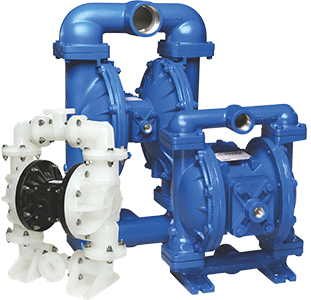

The Sandpiper diaphragm pump is a perfect example of a high-quality, air-operated double diaphragm pump. Sandpiper is a well-known brand in the industry and has been producing pumps for over 50 years. Their diaphragm pumps are designed to be reliable, efficient, and easy to maintain.

One of the unique features of Sandpiper diaphragm pumps is the patented air valve system. This system ensures that the pump operates at maximum efficiency, reducing air consumption and extending diaphragm life. The air valve system also reduces the amount of pulsation, which can reduce wear and tear on the pump and other components.

Sandpiper diaphragm pumps are also designed with versatility in mind. They can handle fluids with high viscosity, solid content, or even shear-sensitive fluids without causing any damage to the product. The pumps can also operate at a wide range of temperatures, making them suitable for use in extreme conditions.

Another benefit of Sandpiper diaphragm pumps is their ease of maintenance. The pumps have a modular design that allows for quick and easy replacement of parts. This feature reduces downtime and maintenance costs, making the pumps a cost-effective solution for many industries.

In conclusion, the air-operated double diaphragm pump is a versatile and efficient pump that can handle a wide range of fluids. Portable pumps are an excellent option for industries that require mobility, and Sandpiper diaphragm pumps are a reliable and high-quality choice. The patented air valve system, versatility, and ease of maintenance make Sandpiper diaphragm pumps a top choice for many applications.

Market Landscape and Ongoing TrendsThe air-operated double diaphragm pump market is expected to grow at a CAGR of 5.5% from 2021 to 2026. The increasing demand for AODD pumps from various industries, including chemical, oil and gas, and food and beverage, is driving the market’s growth. The demand for portable pumps is also expected to increase, especially in industries where mobility is critical.

The latest trend in the air-operated double diaphragm pump market is the increasing use of IoT and automation technology in pump systems. IoT technology enables pump systems to monitor and control pump performance in real-time, optimising efficiency and reducing maintenance costs. The use of automation technology in pump systems also reduces the risk of human error, improving safety and reliability.

Another ongoing trend in the air-operated double diaphragm pump market is the increasing demand for eco-friendly and energy-efficient pump systems. Many industries are focusing on reducing their carbon footprint and energy consumption, and pump systems play a critical role in achieving these goals. Manufacturers are developing pump systems that use advanced materials and designs to reduce energy consumption and improve efficiency. For example, some manufacturers are developing diaphragm pumps with low-friction materials that require less energy to operate. Others are developing pumps with advanced control systems that optimise pump performance and reduce energy consumption.

In addition to eco-friendliness and energy efficiency, manufacturers are also focusing on improving pump reliability and durability. They are developing pumps with longer lifetimes, reduced maintenance requirements, and improved resistance to wear and corrosion.

Overall, the air-operated double diaphragm pump market is growing, driven by increasing demand from various industries and ongoing advancements in pump technology. The market is expected to continue to grow in the coming years as manufacturers develop more advanced and efficient pump systems to meet the needs of a wide range of industries.