A complete LPG (Liquefied Petroleum Gas) solution refers to a comprehensive set of services and products that cater to the energy needs of an industry using LPG as a fuel source. It includes aspects such as LPG supply, installation services, and various products to help save energy in industrial activities.

Incorporating elements like an LPG compressor, LPG bottling, cylinder filling, and LPG transfer into the solution can further enhance its effectiveness. For instance, an LPG compressor helps in the efficient transfer and storage of the gas, while cylinder filling and bottling ensure safe and convenient usage.

A complete LPG solution is vital for industries as it provides a reliable, cost-effective, and eco-friendly energy source that can significantly enhance productivity.

The Heart of LPG Handling: Understanding the Role of LPG Compressors An LPG compressor is a crucial component in a complete LPG solution. It plays a vital role in the efficient transfer and storage of LPG. Here are some key points about the role of an LPG compressor:- Transfer of Gas: The primary function of an LPG compressor is to transfer gas from one tank to another by pressurising the storage tanks. This process is achieved by creating a pressure difference, causing the gas to flow from the higher-pressure tank to the lower-pressure tank.

- Increase in Gas Pressure: LPG compressors are reciprocating machines that pressurise the gas and increase its pressure. This increased pressure is essential in applications where high-pressure LPG is required, such as in industrial processes, fueling stations, or storage systems.

- Vapour Recovery and Recycling: An LPG compressor is also used for vapour recovery and recycling, making it an environmentally friendly solution.

- Construction and Operation: An LPG compressor typically has a single stage and operates on the principle of reciprocation. It has capacity control at 0%, 50%, and 100% and uses forced feed lubrication. The displacement of the piston is provided by suction and press valves. An LPG compressor is an integral part of a complete LPG solution, ensuring efficient transfer, storage, and utilisation of LPG in various industrial applications.

- LPG Bottling: The bottling system of LPG in the cylinder is a crucial part of the LPG solution. The process involves checking the cylinders for safety, repairing them if necessary, and then running them on a chain conveyor line for the filling process. Various online equipment is used for cylinder filling. This process ensures that LPG is safely contained and ready for distribution.

- Cylinder Filling: This is the process where LPG cylinders are filled either automatically or manually. The automatic filling system is safe and effective. You should inspect the cylinder to make sure it’s okay before you fill it again. If needed, you should also wash and dry it before adding more stuff inside. To avoid gas leakage from the cylinder valve, the “O” ring must be checked before gas filling. After putting the cylinder body weight in, a modern machine carousel runs to fill the LP gas in the cylinder.

- LPG Pumps: An LPG pump is a centrifugal pump used for handling liquefied hydrocarbons, such as propane, butane, propylene, and ethylene, in refineries for the distillation of crude oil. These pumps come under the general heading of LPG and are pumped at about minus 104 ºC. They play a crucial role in transferring LPG from storage facilities to various points of use within an industry.

Together, these components form an integral part of a complete LPG solution, ensuring efficient transfer, storage, and utilization of LPG in various industrial applications.

LPG Transfer Systems: Ensuring a Smooth Flow in the LPG Supply Chain LPG transfer systems play a crucial role in ensuring a smooth flow in the LPG supply chain. Here are some key points about the role of LPG transfer systems:- Transportation of LPG: LPG transfer systems are primarily used for the transportation of LPG from storage facilities to various points of use within an industry. This includes transferring LPG from offshore terminals to onshore storage facilities.

- Efficient and Safe Transfer: These systems are designed to facilitate the efficient and safe transfer of LPG. They use flexible hoses that adapt to the motions of the vessel, connecting the vessel to the Pipeline End Manifold (PLEM) placed on the seabed. This ensures that the LPG is transferred safely and efficiently from the vessel to the onshore storage facility.

- Prevention of Diversion: LPG transfer systems also play a crucial role in preventing diversion and leakage in the LPG supply chain. By moving LPG in the supply chain at one market price, these systems eliminate the incentive for diversion, ensuring that the LPG reaches its intended destination.

- Role in the PAHAL Scheme: In India, for instance, the PAHAL (DBTL) scheme was designed to ensure that the benefit meant for genuine domestic customers reaches them directly and is not diverted. This has been acknowledged by the Guinness Book of World Records as being the largest cash transfer programme (households).

LPG transfer systems are an integral part of a complete LPG solution, ensuring efficient transfer, storage, and utilisation of LPG in various industrial applications.

The best LPG solutions from IDEX

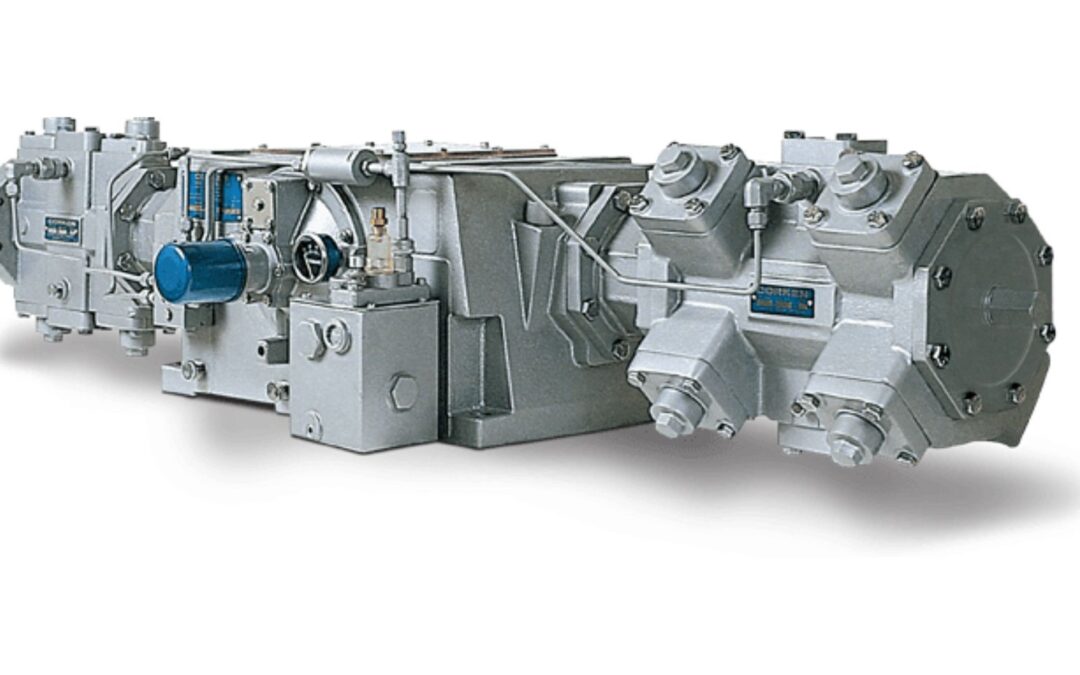

Corken, a part of IDEX Corporation, is recognised as a leading manufacturer of industrial compressors, pumps, and accessories for LPG and other flammable, volatile, and toxic liquids and gases used in the process gas, energy, utilities, transport, and marine industries.

Here are some of the best LPG solutions provided by Corken:- LPG Transfer Solution: Corken’s LPG transfer solution includes air-cooled and non-lubricated reciprocating compressors that comply with API 618 guidelines. These compressors are used for both liquid transfer and vapour recovery of LPG from railcar wagons, road trucks, or Emergency Rescue Vehicles (ERV) to another storage. The compressor creates a pressure differential between the storage facility and the railcar, causing the liquid product to flow in the direction of lesser pressure.

- Cylinder Evacuation Unit: This unit is used to discharge gas from inside defective LPG cylinders. The discharged LP gas is transferred to the LPG storage tank by this unit to be reused.

- Decommissioning of Storage: Vessels, and Pipelines: Corken compressors are used for transferring liquid and gas to another storage to avoid gas loss using the same principle as tanker or rail car unloading.

- Industrial Gas Compressor Solutions: Corken offers a wide variety of industrial compressor solutions for liquefied petroleum gases (LPG) and other petrochemicals. Applications include Road Tanker or Rail Wagon unloading, Mobile Mounted units for Emergency Rescue vehicles for Gas recovery, Cylinder Evacuation, and Process Gas boosters.

- Industrial Pump Solutions: Corken provides pumping solutions for the chemical, petrochemical, petroleum, oil and natural gas, liquefied gas, and truck and transport industries. The industrial pump collection consists of two types: one is called “regenerative turbine,” and the other is “positive displacement sliding vane.”

Corken offers comprehensive LPG solutions that ensure efficient transfer, storage, and utilisation of LPG in various industrial applications.

Conclusion

A complete LPG solution is not merely a convenience but an essential component for various industries seeking efficient, reliable, and eco-friendly energy solutions. The comprehensive LPG solutions offered by companies like Corken, a part of IDEX Corporation, play a pivotal role in ensuring the seamless flow of LPG in the industrial supply chain. These solutions encompass LPG compressors, cylinder filling, LPG pumps, and LPG transfer systems, all of which are designed to enhance the efficiency, safety, and environmental sustainability of LPG usage. With a strong emphasis on innovative technologies, quality, and compliance with industry standards, these solutions stand as the ideal choice for industries looking to optimise their energy needs. Opting for a complete LPG solution is not only a matter of convenience but also a strategic move towards improved productivity, cost savings, and environmental responsibility.