A ball valve, a vital element in piping systems, functions as a unidirectional valve that can be easily operated by applying pressure to a spherical ball positioned within a concave aperture. As per its dictionary definition, a ball valve offers a straightforward and efficient method for controlling fluid flow in various applications.

What are ball valves used for?

Ball valves are used as fluid shutdown valves in onshore and offshore oil and gas production facilities. Another primary use of ball valves is to supply furnaces using fuel gas systems. With the least amount of pressure loss, ball valves can regulate the flow of high-pressure gases and liquids. Since these valves offer a very low response time and are designed to have low-torque tight-sealing capability, one can open and close them quickly.

One of the USPs of ball valves is that they can be easily installed in a variety of remote locations within the petrochemical industry. Since most oil and gas facilities are located in far-flung areas, a valve that is non-complicated and easy to operate and repair makes a lot of sense for them.

Adaptable by design, ball valves come in a variety of forms, including reduced bore, full bore, V-port, floating-type, and true-union. At low pressure, a floating ball valve performs well. They are smaller and have a simple design, which works well under low to moderate pressure. At high pressure, there is a risk of seat deformation, resulting in a compromise of the sealing qualities of the valve. If you need to operate applications involving high pressure and temperature, you should opt for a ball valve with a metal seat, which can withstand a much higher pressure without getting deformed. In case you need to handle hazardous and inflammable fluids, you should also consider an emergency seat seal when purchasing your ball valves. Made of metal, these emergency seat seals are attached adjacent to the ball. In the event of a fire, the ball moves against the metal seal. You may want to go for materials like brass, aluminium, steel, or cast iron for the body of the seat seal for an extended duration of operation. Not just that, the packing material must be fireproof as well.

Which ball valve is best?

There are several kinds of ball valves. However, the two main types of metal ball valves are brass valves and stainless steel valves. Both ball valves are used in numerous pipeline applications to control the media flow that passes through oil pipelines. The advantages of brass ball valves include optimal corrosion resistance and easier sealing (because the alloy is much softer than steel). Brass ball valves can be both leaded and non-leaded. For drinking water pipelines, the non-leaded option would be ideal so that the valve doesn’t release any lead into the moving water. However, with non-leaded options, it is important to keep checking for corrosion, which can also contaminate the water.

Steel valves are compact in design and, hence, easy to operate and maintain. The durability and strength of steel ball valves make them suitable for handling high-pressure and high-temperature gases and liquids. Steel ball valves also offer excellent sealing; they can be closed by applying a small torque with a 90-degree rotation. This feature is absolutely essential in industries where operators can’t afford even a minor leakage (owing to environmental concerns, for example). Because of their strength, steel ball valves can be used for a long period of time. Since steel is resistant to corrosion, steel ball valves can be used for marine water and commercial brewing systems.

Which valve is best for control?

To find the valve that will give maximum control, it is important to understand the user’s requirements and application type. Ball valves usually offer excellent control of liquid flow. Check valves close if the fluid is reversed, so they offer control when it comes to the reversal of fluid. Butterfly valves, on the other hand, are typically used by the oil and gas industry, where they clean themselves. When open, there isn’t much pressure drop. If an operator wants full flow or no flow, then gate valves are ideal.

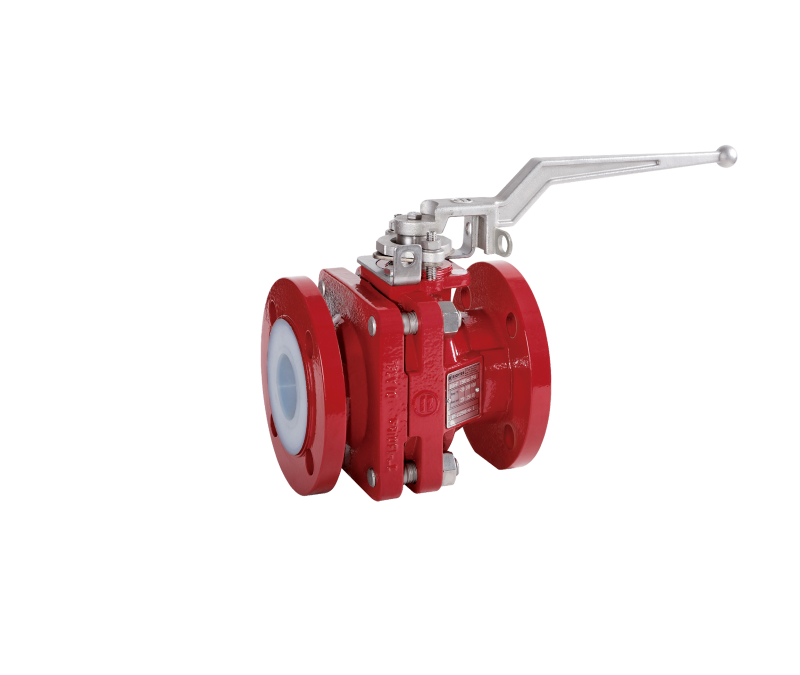

Top Ball valve manufacturersIndia boasts a selection of renowned ball valve manufacturers, showcasing their expertise in the industry. Among all the manufacturers, IDEX India stands out for its commitment to delivering top-quality ball valves that excel in performance, durability, and reliability. Their ball valves feature the innovative ENVIPACK stuffing box sealing system, designed to withstand even the harshest operating conditions. With an emphasis on precision engineering and adherence to international standards, IDEX India’s ball valves boast impressive specifications, including ASME/ISO/DIN designs and a robust pressure rating of ASME 150 or 16 bar.

One of the key advantages of IDEX India’s ball valves is their PFA lining, which provides excellent resistance to corrosion and chemical attack. This lining ensures that the valves can effectively handle corrosive substances across various industries. Moreover, these ball valves are engineered to withstand extreme temperature ranges from -60 °C to +180 °C (-80 °F to +360 °F), making them suitable for applications involving caustic soda, process and dry air, H2SO4, HCI, brine, and more.

With IDEX India’s high-quality ball valves, industries can rely on efficient and precise control of fluid flow, ensuring smooth and reliable operations. These valves are built to withstand demanding environments, offering long-lasting performance and reduced maintenance requirements. Whether it’s for industrial processes or critical applications, IDEX India’s ball valves deliver the reliability and performance that industries in India and beyond require.