In industries and other applications, a dosing pump is used as a specialised type of positive displacement pump to inject precise quantities of chemicals or substances into water flow or other mediums like gas and steam with accuracy and consistency for controlled chemical delivery purposes.

The Uses of Metering Pumps

Various industries utilise

Dosing pumps for a variety of purposes, such as adjusting pH levels or disinfectant addition in water treatment processes and accurate ingredient measurement in food processing operations, as well as in manufacturing plants and agricultural and mining activities too. Dosing pumps are employed in labs for precise chemical dispensation and can function effectively even in high-pressure settings.

Varieties of Dosing Pumps

Different dosing pumps have unique mechanisms.

- Diaphragm pumps utilise a combination of diaphragms, pistons and valves to fill and empty chambers.

- Peristaltic pumps employ rollers to compress flexible tubes.

- Plunger pumps use reciprocating plungers to displace liquids.

- Solenoid pumps are powered by electromagnetic solenoids.

Structural Elements of a Dosage System

The dosing system includes a container or tank along with a pump featuring an inlet pipe for suction and a dosing pipe for delivery, an injector and foot valve, all controlled by a system setup. The chemical container stores the substance to be dosed while the pump pulls it through the suction line and sends it to the injector, which acts as a one-way valve allowing entry of the chemical. The foot valve plays its part in maintaining prime for the pump operation. The dosing line refers to a tube or a reinforced hose that transports the chemical to the injection site while the control system guarantees precise dosing accuracy, which can range from basic timers to advanced SCADA systems.

The Operational Concept of a Dosing Pump

Pumps that dose out liquids operate by employing either a diaphragm or a piston to create cycles of suction and discharge. The diaphragm piston serves to separate the liquid from its driving force. The flow direction is managed by valves. In diaphragm pumps, a flexible diaphragm moves back and forth to push and pull the liquid. Piston pumps, on the other hand, use a reciprocating piston to draw in and expel the liquid. Electric motors, pneumatic motors, and driven mechanisms are used to power diesel pumps. These pumps provide varying flow rates and can be finely tuned for accuracy. Safety precautions such as leak detection sensors and safe mechanisms are crucial to ensure safety in various situations where pressure may build up excessively.

Dosing Pumps and Their Roles in Proportional Dosing

Proportional dosing involves adjusting the amount of chemicals or additives based on specific signals received to maintain accuracy in the process control system operations. Dosing pumps are instrumental in ensuring this precision by dosing in proportion to a pulsed input signal typically generated by a water meter or a process controller equipped with Pulse Frequency Modulated (PFM) output capability. This enables flow-based dosing methods such as sodium hypochlorite dosing corresponding to water flow rates and pH adjustments where acid or alkali is added to regulate the pH level within specified limits. The dosing pump can change how often it pumps or the number of pumps based on the signals it receives to accurately measure chemicals. The pump speed can be controlled by a 4–20 mA signal that dictates how many times it pumps in a minute. Below 4 mA, the pump stops pumping altogether, while at 20 mA, it pumps at its rate capable of being adjusted using a potentiometer. Certain pumps offer options to adjust the range of the 4–20 mA signal. Using dosing pumps to deliver doses presents advantages like precision in measurements and reduction in chemical consumption while ensuring proper pH levels and enhancing safety and efficiency in water treatment and industrial settings.

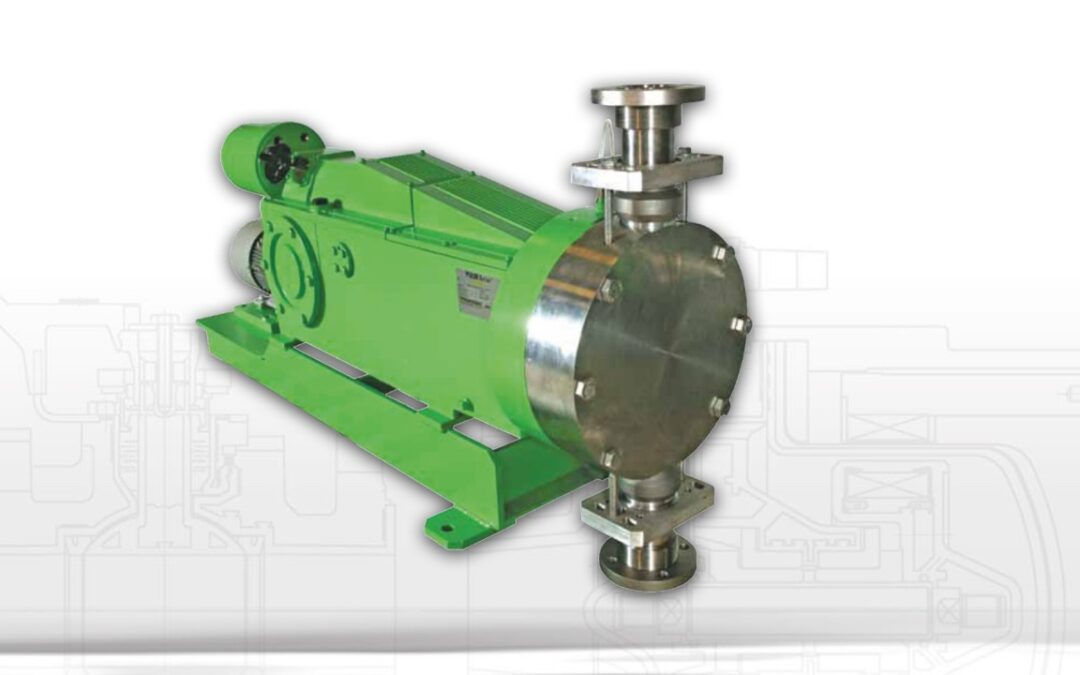

IDEX Pulsafeeder Dosing Pump

IDEX Pulsafeeder is a leading manufacturer of dosing pumps, offering the Pulsatron Series E with a flow range of 0.018 gph to 170 gph (0.068 lph to 643 lph), pressure up to 4,000 psig (275 bar), temperature up to 230°F (110°C), viscosity beyond 3000 cPs, and turndown capacity adjustable up to 1000:1. These pumps offer accuracies of +/-0.5% of the set point and are used in various applications like cooling tower treatment, automotive manufacturing, water and wastewater treatment, and other industrial processes. Pulsafeeder adheres to ISO 9001:2015 quality standards and has field-tested pumps that meet or exceed expectations. IDEX Pulsafeeder offers a wide range of solutions for accurate chemical dosing.

Conclusion

Pumps for dosages are instruments for accurately delivering chemicals in different industries because they provide precise dosages and flexibility while being capable of managing various types of chemicals effectively. It is important to have a grasp of the various kinds of dosage pumps available along with their components and operational principles to choose the most suitable pump for your particular requirements wisely. To guarantee trustworthy chemical dosages in your operations, consider factors like the properties of the fluid being used, flow rates, level of accuracy needed, and the type of pump being employed.