Quadro Liquds

Quadro Engineering has been the trusted partner of the world’s leading pharmaceutical, food and chemical processing companies for over four decades.

Liquids Processing & Powder Dispersion Expertise

Quadro® is a high shear mixer manufacturer that designs and manufactures single-pass, inline high shear mixing equipment for powder incorporation and dispersion into liquids, in addition to liquid-into-liquid mixing and homogenizing. We pride ourselves on being the mixer manufacturing company that provides the solutions and experience that other businesses cannot.

Personal Care & Cosmetics

Pharmaceutical

Food

Chemical

The Future Of

Fluid Mixing

Is Now

Quadro® is a mixer manufacturing company and disperser manufacturer that thinks outside the box. Our innovative solution to the limitations of in-tank mixing — single-pass, inline processing — delivers industry-leading performance, predictability, repeatability, ease of maintenance and long-term reliability.

We continually advance our understanding of the science behind shear energy and dispersion through extensive R&D in our state-of-the-art in-house test center. As an expert mixer manufacturer, our innovative solutions exceed expectations and break traditional assumptions about processing limitations.

We help you solve today’s mixing problems — and tomorrow’s challenges.

High Shear Mixer Products

Engineered to Deliver

Our product line consists of high shear homogenizer & wet mills, inline powder dispersers, inline continuous processers, inline emulsifier mixers and in-tank mixers..

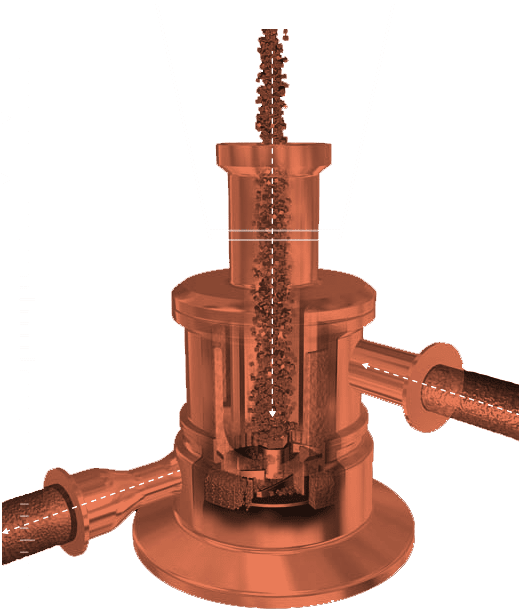

Inline Powder Disperser

Quadro Ytron® ZC – High shear single-pass disperser designed for the most difficult-to-wet powders, thickening agents and rheology modifiers. This powerful high-speed disperser is uniquely engineered for use in personal care, cosmetics, pharmaceutical, chemical, and food & beverage applications.

Inline Continuous Processing

Quadro® CDS – Combines the enhanced performance and benefits of the Quadro Ytron® ZC with our Uniform Film Interface (UFI) technology to continuously disperse powders into a controlled liquid stream.

High Shear Homogenizer & Wet Mill

Quadro® HV – Unique high-velocity rotor/stator mixer for submicron homogenizing, high shear wet milling and suspension micronization..

Inline Emulsifier Mixer

Quadro Ytron® Z – Multi-row toothed rotor/stator inline mixer designed to reduce bypassing in macro-emulsion processing, homogenization, modifying product textures and fine particle dispersions. Best-in-class consistency meets flexibility and scalability with this powerful mixer.