Matcon has been a trusted name for over 40+ years for delivering IBC powder & tablet handling systems & Bin Blenders, from the simple start-up to the more complex automated, multi-mixer, multiple packing line configuration.

We supply world-leading Intermediate Bulk Containers for the processing, storage and transport of bulk material solids, powders, granules, and tablets. Our patented Cone Valve technology is a superb discharging device overcoming all manner of powder flow problems.

Whether considering a new production facility, or upgrading an existing one, the way that powders, granules, tablets and capsules are moved,stored, fed to and collected from processes has a fundamental impact on how the facility operates: its capacity, flexibility, expandability and cost of production.

Our Head Office and a Centre of Excellence Test Plant are in the UK and regional offices and Test Facilities in the USA, China, Singapore, and India. In India, we have testing and production facility at Sanand, Ahmedabad and Commercial office in Mumbai.

IBC Material Handling Solutions for

Pharmaceutical manufacturing

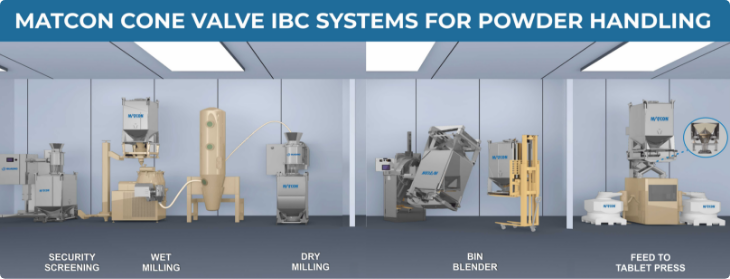

Powder Handling

We solve traditional powder handling issues such as bridging, containment, and blend segregation using our patented Cone Valve technology in each IBC

Tablet Handling

Matcon’s gentle Tablet Handling system enables efficient handling of tablets and capsules. Whilst, at the same time, the effectiveness of tablet coating, printing, inspection, and packing processes are optimized.

Our Customer Experience Centre(CEC) at Sanand,

Ahmedabad was designed keeping in mind the needs of our customers & partners and to help them resolve their challenges and handle the most critical applications. A demo pharma plant has also been set up to exhibit the application of our products in the customer’s manufacturing processes.Matcon Product Applications

Whilst the products that you produce might be very different, the issues you have with

production or your powder processing challenges can be very similar.