Centrifugal Seal-less Magnetic Drive Pumps – Benefits and Applications

IDEX India is a leading global manufacturer of highly engineered industrial products and technologies such as industrial pumps & valves, compressors, flow meters, milling equipment, dispensers, firefighting tools and rescue equipment, spare parts, services, and accessories.

IDEX has an efficient team at front-end sales, technical, and service composed of highly qualified, globally networked professionals working passionately from different places of the country, closely associated with the channel partners and counterparts across the world, with accessible local accessibility.

What are Centrifugal Magnetic Drive Pumps?

In a standard centrifugal pump, the drive shaft from the motor is connected, generally via a flexible coupling, to the impeller through the pump housing.

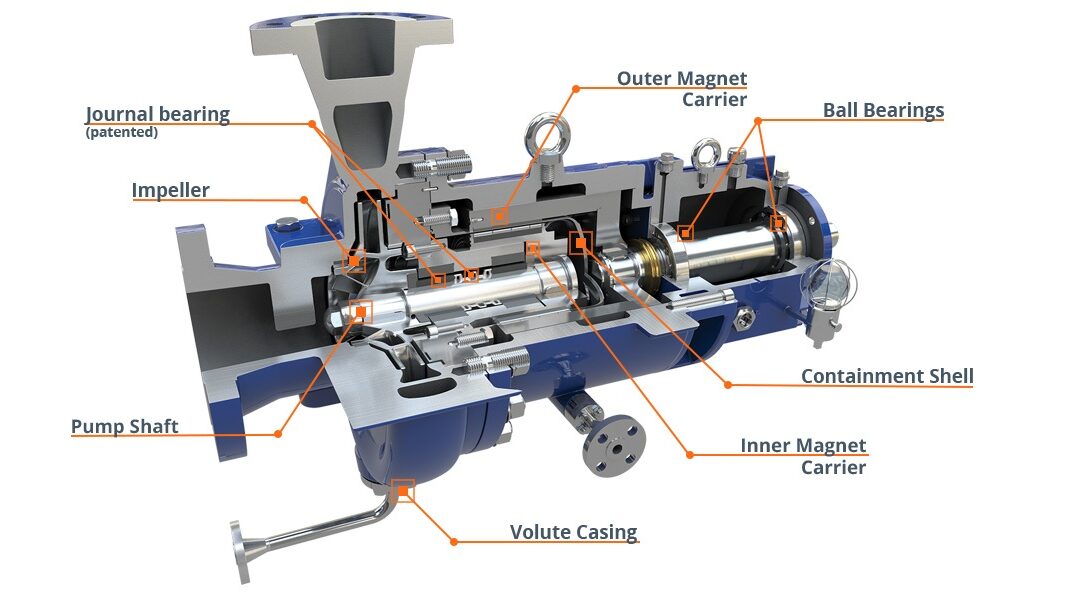

In contrast, the impeller and the pumped fluid are contained within a hermetically sealed housing in the centrifugal magnetic drive pump. The drive shaft from the motor rotates an assembly of magnets on the outside of the housing.

On the inside is a matching ring of magnets where the shaft is attached to the impeller. The torque is transferred through the housing due to the coupled magnets. The motor shaft seal is removed, resulting in the elimination of leaks caused by shaft seal failure. Centrifugal magnetic drive pumps must be used where flooded suction conditions exist.

Seal-less Magnetic Drive Pumps

A seal-less magnetic drive pump is a conventional centrifugal pump without the dynamic seal typically used to seal the pump shaft.

A static containment shell replaces this dynamic seal to form a wholly filled liquid end or pressure boundary, which offers the plant engineering contractors and operators a 100% leakage-free pump.

This design has the highest operational safety, low maintenance, and strict environmental standards. Magnetic drive pumps require less monitoring and maintenance, equating to maximized efficiency and substantial savings over the pump’s life; they are also a more cost-effective option.

Magnetic-driven pumps are an essential class of seal-less pumps used for services in which leakages cannot be tolerated, or liquids are difficult to seal.

Magnetic drive pumps, also known as magnetically coupled pumps, are different from the traditional pumping style. The electric motor (the driver) is coupled to the pump by magnetic means rather than a direct mechanical shaft.

This pump works through a drive magnet that eliminates any shaft sealing required by the pump, a significant advantage in the industry.

These pumps are essentially used where leakage of the pumped liquid poses a considerable risk, such as with aggressive or risky liquids, exotic materials, acids, alkalis, corrosives, pollutants, and toxins, and for ultra-pure liquids and hard-to-seal liquids.

Advantages of Richter Centrifugal Magnetic Drive Pumps

- Low Risk – The design of magnetic drive pumps ensures a low risk of fluid and vapor emissions from being leaked. Therefore, people working on or near the pump are not exposed to hazardous, corrosive, flammable, explosive fluids and other toxic chemicals.

- Reliability – Magnetic drive pumps are reliable and more durable.

- Zero Maintenance – The design of the magnetic drive pumps is simplified, and magnetic drive pumps can go for a decade without needing any repair, which makes them maintenance accessible and cost-effective. This is a seal-less pump, therefore, you don’t need to replace pump seals.

Applications of Magnetic Drive Pumps

The typical applications in which you would use a Richter centrifugal magnetic drive pump are chemical transfer, tank unloading, or heat transfer because the pumps can handle temperatures from -40°C to +180°C.

Other applications where you might use a mag drive pump are when the product is costly, and you want to mitigate the risk of losing any product.

Commonly used in the chemical industry, magnetic drive pumps are ideal for transferring hazardous/dangerous fluids, ultra-pure liquids, and hard-to-seal liquids that can crystallize upon the seals of a pump when exposed to air.

Given the above design benefits, magnetically coupled pumps are commonly used but are in no way limited to the following applications:

- Chemicals

- Hazardous and corrosive liquids

- Cryogenics

- Food and beverage

- Surface Conditioning

- Photo Processing

- Tank cleaning

- Tank to tank transfer

When it comes to operational reliability and safety, Richter is the right partner for you.

For further assistance, we are just a call away on 1800-267-9955 (toll-free) or visit our website today.