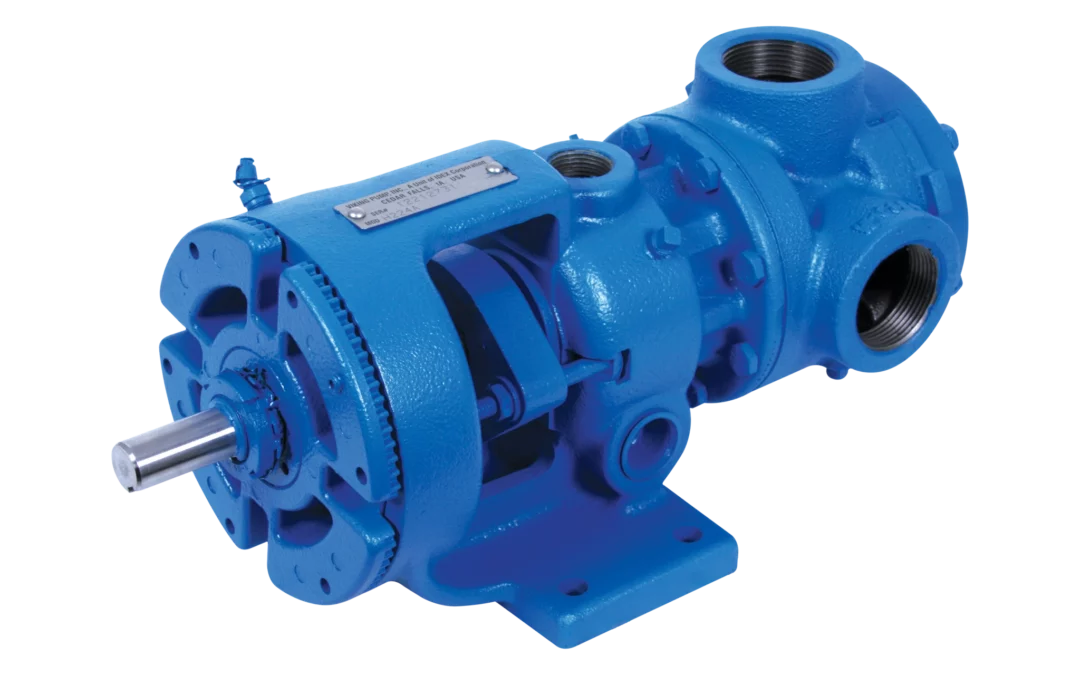

Advantages of Using Vikings Cast Iron Gear Pump to Maximize your Productivity

Viking Pumps has been a leader, innovator and company since its founding in 1911. The internal gear pumps from Viking have been tested for various applications and have proven to deliver quality results.

Invented by Viking Pumps over 100 years ago, the internal gear pump continues to be the company’s best-known product.

With cutting-edge advanced engineering features, Viking is one of the most popular Internal Gear Pump manufacturers. They are ideal for handling corrosive, viscous, and shearing liquids under low to high flow, pressure, temperature, and temperature applications.

With the help of this technology, businesses can conduct their operations more efficiently and effectively. The internal gear pumps are available in various materials, such as Cast Iron, Ductile Iron, Carbon Steel, Stainless steel, Hast alloy etc.

How does a Viking internal gear pump work?

Viking Internal Gear Pumps are reliable, simple, and easy to maintain. This makes them ideal for handling thin liquids, fuel oil and solvents, as well as thick liquids such as chocolate, asphalt and adhesives.

The internal gear pump is a positive displacement rotary pump that moves fluid by rotating the pumping elements. There are two gears in the Viking internal gear pump – a drive gear called the rotor and a driven gear called the idler. The idler gear fits within the rotor and rotates along with it. The rotor is attached to the shaft, which is coupled with a driver (generally an electric motor) that drives the pump.

The gears unmesh at the suction side of the pump and create a vacuum, pulling the liquid into the pump. This liquid is carried to the discharge port. At the discharge port, the gears come into the mesh, causing high pressure and discharge of the liquid. The crucial aspect is that the pump does not develop any pressure during the entire process. It overcomes the back pressure and positively transfers the liquid from one end to another. The back pressure it can work against is directly proportional to the power it gets from the driver.

The internal gear design can handle various viscosities and provide unparalleled efficiency in numerous industrial applications. Because of its unique design, flexibility and easy maintenance, Viking is known as the leading cast iron gear pump manufacturer in India.

Cast iron gear pumps come with a range of additional features and advantages that are certain to improve the performance and concreteness of the work. These pumps are recognized for offering an excellent power density in a small package; while they are also known for their dependable, durable performance under high pressure.

Common internal gear pump applications include, but are not limited to:

- All varieties of refined fuels & lubricants

- Resins & polymers

- Alcohols & solvents

- Asphalt, bitumen & pitch

- Polyurethane foam (isocyanates, polyols & additives)

- Food products such as corn syrup, chocolate & peanut butter

- Paint, inks & pigments

- Soaps & surfactants

- Heat transfer fluids

Why choose a Viking internal gear pump?

Viking Pump was founded by Jens Nielsen, who invented the internal gear pumping principle. As described above, it uses two rotating gears which un-mesh at the pump’s suction side to create voids that allow atmospheric pressure to force fluid into the pump.

It offers the following:

- The broadest selection of materials, designs, seals, ports and displacements

- Adjustable clearances enable handling viscosities from 28 to 2,00,000 SSU (1 to 440,000 cSt)

- Low shear

Advantages of using internal gear pumps

- Custom Designed Solutions: The company offers a wide variety of materials of construction (MOC) options, including cast iron, ductile iron, steel, stainless steel, and other alloys

- Easy To Maintain: It is simple to use due to the presence of only two moving parts i.e. the outer drive gear (rotor) which turns the inner drive gear (idler), providing superior flexibility in most challenging applications.

- Multiple Porting Options: Viking offers the broadest selection of porting options that provide easy solutions to match customer requirements

- Adjustable End Clearances: It offers an unparalleled range of viscosities and temperatures or to compensate for wear over time

- Several Seal Options: The gear pump comes with a wide range of shaft seal options including packing, lip seal, cartridge seal and sealless mag drive providing easy seal change depending upon application needs

- One Shaft Seal: The one shaft seal design provides a more reliable and lower cost than two or four seals used on timed lobe and screw pumps

- Uniform Discharge: The internal gear pumps offer constant and even discharge regardless of pressure conditions to minimize downtime and maximize output

With the wide variety of pumps available in the market today, it is sometimes complicated to analyze which one is best suited for your application to handle the viscosity of the fluid or generate the proper flow and pressure.

Our experts at IDEX India are well-versed in Viking internal gear pumps and can provide you with a consultation to help you make an informed decision. We offer custom-designed pumping solutions to fit your specific application requirements.