Matcon for Food & Beverage Market

Matcon offers complete powder handling systems for various sector in Food & Beverages industry with the equipment they need to improve flexibility and production capacity & increasing operational effectiveness.

Matcon Solution for Food and Beverage Segments

Mixing challenges for Nutraceuticals industry

An increase in diverse recipes and product portfolios means more changeovers during a shift. This significantly impacts on active production time.

Many powders used in nutraceuticals products are notoriously difficult to handle and can be sticky and poor flowing. Some of these powders have a tendency to segregate during discharge. More and more, recipes need to be allergen free or diet specific, which will result in extra time time being spent carrying out thorough clean-downs between recipe batches.

Matcon solution for Nutraceutical Industry

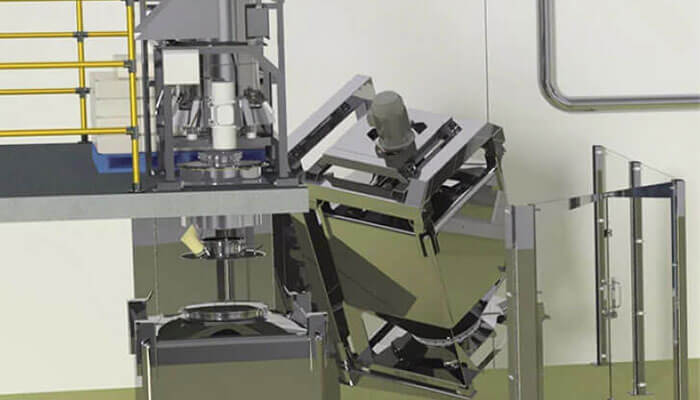

Matcon IBC Systems are designed to optimize your production line and make it more flexible. By employing parallel processing, the manufacturing process steps (formulation, mixing, packing and cleaning) are decoupled, with each process step taking place independently.

The act of separating these manufacturing stages creates the potential for multiple processes to take place simultaneously, allowing manufacturers to produce more than one batch or different recipe batches at any given time, hence becoming more efficient.

Our unique Cone Valve Technology located within each IBC protects your blended powders during the discharge process, maintaining their integrity and quality.

IBC blending means that you spend less time cleaning and significantly reduce the risk of cross-contamination across your product lines as all powders are kept within the IBC.

Flavourings & Seasonings

Mixing challenges for food flavouring and seasonings manufacturers

Recipes often contain powders with very different bulk densities & particle sizes, causing segregation of the mix on transfer.

Some powder mixes can become cohesive & poor flowing, which slow the line whilst blockages are cleared.

A coupled production line that is unable to meet diversity or consumer demands. Dusty environments create cross-contamination risks and pose health risks to staff.

Matcon solution for Food Flavouring and Seasonings Industry

A system designed to optimize production flow is what we do. Providing full batch traceability and batch integrity throughout the complete production process.

By employing parallel processing, the manufacturing process steps (formulation, mixing, packing and cleaning) are decoupled, with each process step taking place independently, maximizing process efficiency and Overall Equipment Effectiveness (OEE).

Our unique Cone Valve Technology located within each IBC handles all powder types & protects your mixed powders during transfer, maintaining their integrity and quality.

Its closed system design gives full dust containment for a cleaner environment and operator safety.

Bakery & Confectionary

Mixing challenges for bakery manufacturers

With an increase in allergen awareness, consumer demand has pushed the responsibilities on to manufacturers. Failure to effectively manage allergens in the production process not only impacts reputation and profitability, it ultimately leaves you open to prosecution.

Increasing product variety is difficult to handle on traditional in-line fixed mixer systems due to the need for full clean-down each time recipes are changed.

Make-to-order recipes with shorter lead times can be hard to achieve if the production schedule isn’t flexible which necessitates a need for inventory storage and floor space.

New product lines increasingly contain allergens or are gluten-free which places more demand on equipment hygiene standards.

Matcon solution for Bakery & Confectionary Industry

Our hygienically designed IBC System provides a good ROI on high variety bakery production schedules and facilitate manufacturers to ‘make-to-order’ rather than run a ‘campaign’ production process.

In-bin IBC blending eliminates cleaning down-time on recipe changeovers at the mixing stage. The system remains closed at all times as all bakery powders are contained within the IBC, eliminating any risk for cross contamination and offering dust containment for a cleaner environment and operator safety.

Simply and easily switch IBCs in & out of the process without worrying about any allergen cross-contamination.

Matcon Solutions

Matcon for Pharmaceuticals

IDEX India facility

Idex India Manufacturing Facility

- Dedicated 5000 sq.ft. area for local assembly & manufacturing of entire material handling systems of Powder & Tablet Handling IBCs, Cone Valves, Blenders, Discharge station

- Engineering & project management capabilities to support you in designing and implementation across the project lifecycle

- Trained resources from Matcon for sales & service across India for immediate assistance